- Home /

- Hand Scraped Natural Acacia Flooring - 7.5"

About Engineered Flooring

Description

Hardwood Bargains' 7" wide Hand Scraped Natural Acacia flooring is a durable and stylish option for any space. The hand-scraped finish adds a unique, rustic touch to the acacia wood, which is known for its resistance to scratches and dents. This flooring comes with a 50 year finish warranty, ensuring that it will retain its beautiful appearance for years to come.

In addition to its durability and aesthetic appeal, this flooring is easy to install and maintain. The 7" width makes it perfect for small rooms or spaces where a wider plank may not fit. The easy-to-clean surface allows for quick and effortless upkeep, so you can enjoy your beautiful new floors without worrying about maintenance.

The 50 year finish warranty offered by Hardwood Bargains is a great added benefit, giving you peace of mind that your investment will be protected. This warranty covers any issues that may arise with the finish of the flooring, such as peeling or fading, so you can enjoy your floors for years to come. With its high-quality construction and stunning natural acacia wood, this flooring is a smart choice for anyone looking to upgrade their home.

Specifications

- SKU

- HWB-F-0422

- Product Type

- Engineered

- Connection

- Tongue & Groove

- Finish

- UV Oil

- Style

- Hand Scraped

- Color

- Natural

- Collection

- Riviera

- Width

- 7.5"

- Length

- 71" (Random Length) Random length flooring is flooring that comes in boxes or cartons made up of varying plank lengths. This gives the floor a natural look and prevents patterns during installation, efficiently maximizing all of the lumber used in milling.

- Thickness

- 3/8"

- Wear Layer

- 1.2mm

- SF Per Box

- 31.09

- Weight/SF

- 1.7 lbs

- Weight/Box

- 52.2 lbs

- Finish Warranty

- 25 Years

- Structural Warranty

- Lifetime

- Install Options

- Float Glue Nail

- Maintenance

- UV Oil Guide

Frequently asked questions

What is tongue & groove construction?

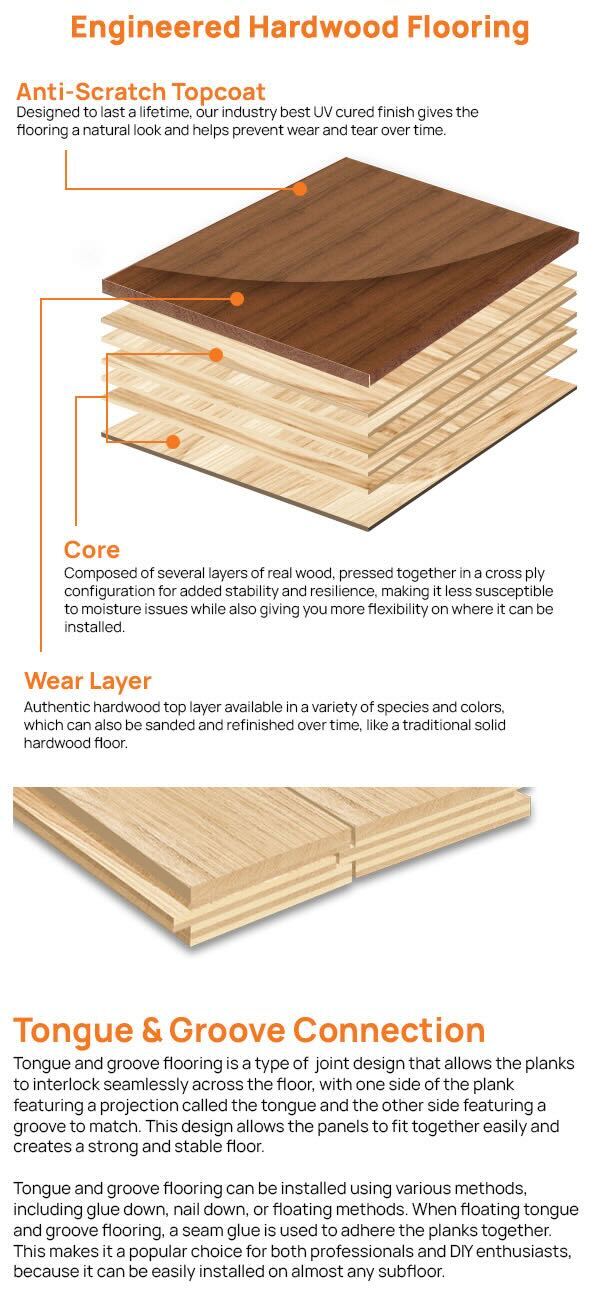

Tongue and groove is the type of joint construction on wood flooring planks that allow them to easily fit together. One side of the plank has a projection called the tongue while the other side has a groove to match. The panels are laid flat with each tongue fitting into the groove next to it. This allows the planks to interlock seamlessly across the floor. Tongue and groove flooring can be installed in either a glue down, nail down or floating method. If floating tongue and groove, a seam glue is used to adhere the tongue and groove together.

What is an engineered floor?

Engineered hardwood planks are essentially a sandwich consisting of a specific species of wood on top (generally 1/16” - 1/8”) with a high quality plywood core or high-density fiberboard bottom (HDF). They often come in a click and lock or tongue and groove construction that can be easily floated over your subfloor as well as glued or nailed down. Engineered floors need about 2-3 days to acclimate in the room/home prior to being installed.

What are the benefits of an engineered floor vs a solid floor?

Both types of flooring have their pros and cons, so we always recommend speaking with one of our flooring professionals first to determine what fits your needs and style best. Engineered can be installed both above or below grade as engineered flooring is less susceptible to moisture and expansion, versus solid wood floors which can only be installed above grade as they are one solid piece of wood and can only sustain a certain amount of moisture before expansion and movement becomes an issue. Another benefit to Engineered hardwood is they can be installed in almost any fashion. You can glue or nail both engineered and solid hardwood flooring when it comes time for installation, but you can also float engineered floor over most subfloors (as we discuss later a very DIY friendly and cost effective form of installation). This is because engineered floors often come in a click and lock or tongue and groove construction which allow for easy installation and locking. Solid floors take more time to acclimate as well, which if time is an issue for installation, becomes an important factor. Engineered hardwood takes about 2-3 days of acclimation in your home prior to installation whereas solid is 2-3 weeks.

What are the benefits of a UV-cured oil finished floor?

Modern Style - Most homeowners invest in hardwood floors because they appreciate the look of real wood. That distinctive natural grain, texture, and color set hardwood apart from many other synthetic flooring materials by adding a sense of genuine beauty to your living space. UV oil finishes capture the spirit of wood and preserve that native beauty for years and years. This allows you to more fully appreciate it. Durable and Forgiving - High-gloss finishes tend to show scratches easily due to the amount of light reflected, flooring manufacturers have adapted to semigloss or matte finishes in recent years. With UV oil finished hardwood flooring you can hide these small markings due to the matte finish reflecting low light. A soft matte finish helps markings and dents blend into the existing grain, without a noticeable contrast in the topcoat. Environmental Safety - UV finishes are low in volatile organic compounds, or low-VOC. That equals better indoor air quality and overall safer environment for floor owners. The increased durability also creates a longer life of the finish and floor, reducing impact on the life cycle of the floor.

How can this floor be installed?

Floating floor installation can be done on almost any sub floor (wood, OSB, concrete, or even existing floors). The term floating refers to the fact that the planks do not need to be nailed or glued down. Floors that can be floated come in a click and lock or a tongue and groove construction. You need to purchase a wood seam glue that will resist moisture and hold the flooring together. A protective pad or underlayment is generally place underneath a floating floor to limit the transmission of sound when walking and as a protectant against moisture.

Glue-down installation process is when the floor is glued to the subfloor using a special flooring adhesive. From a do-it-yourself standpoint, this is generally considered the hardest of the installations and requires a high skill level. As with with nail down, it is best to have a professional installation crew execute this if you decide to go this route for installing your floors. There are many types of glue that can be used but it is important to get a high quality, waterproof flooring adhesive.

Nail down installation is the process of securing the floor to the subfloor with either nails, staples, or flooring cleats. This method requires significant equipment and a professional installer is generally recommended for these types of installs.